|

Top propellers require top motors

Basically, propellers which slowly turn in the water and have a high pitch

and a large diameter, have the highest degree of effectiveness. A large

propeller diameter results in a high propellant flow, while a high propeller

pitch has a positive effect on the additional speed induced by the propeller.

Multiplied by each other, the propellant flow and the induced additional

speed result in the propulsive power of the propeller. On the other hand, an

increasing circulation speed of the propeller results in an increasing loss

of efficiency.

Conventional outboards in

the low-power range fail at using highly-efficient propellers: Either they

do not have enough torque to move large sloped propellers or they do not

have enough elasticity (availability of torque over a large speed range).

Combustion engines are particularly susceptible to a lack of elasticity.

This is because they only have an extremely low torque at small speeds.

Propellers that would normally have a good rate of efficiency within the

efficient range of the motor stall the motor when within low speed ranges.

The rates of efficiency for propellers that can be used for low-power class

combustion engines are therefore limited to 20-30%.

To ensure that the Torqeedo motor can fully exploit its strengths in the

maximum torque and in elasticity, and then covert these into superior

efficiency, the Torqeedo propeller has been carefully adapted to the torque

characteristic of the motor.

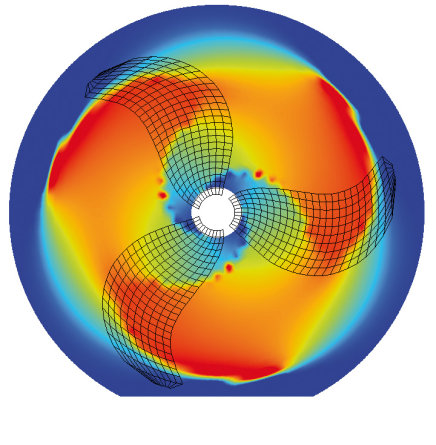

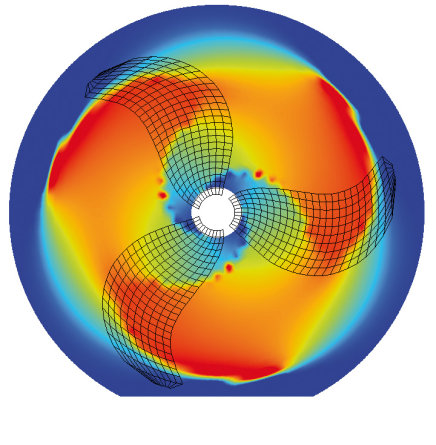

Bleu pour vitesse lente, rouge pour régime élevé

cliquez pour agrandir

Low eddy, high thrust: The Torqeedo propeller from large shipbuilding

The majority of propellers used in recreational activities are based on

series tests that were carried out in the 40’s to 60’s of the 20th century

in the Wageningen test facility in The Netherlands as well as by the US Navy.

The results of these tests have been concretized in general construction

principles and are used by rule of thumb.

On the other hand, the most modern large ships have been equipped for some

years now with propellers that are the result of multi-dimensional

optimization calculations. In contrast to standard propellers, the pitch and

camber of the propeller are not kept (almost) constant across all segments

of the propeller.

Instead, the pitch and camber are optimized based on a vortex grid

calculation for each single segment of the propeller in a stepwise

optimization over many thousand iterations. The additional scope for design

resulting from this allows the additional speed to be induced by the

propeller at the highest rate of efficiency.

Due to these characteristics, the corresponding propeller is designated as a

Variable-Pitch-Variable-Camber (VPVC) Propeller

No compromises: hydrodynamic shaft

Torqeedo outboards are

uncompromisingly trimmed to efficiency. This also applies to all fluidic-sensitive

components such as the shaft and the pylon

legal mentions - Copyright

Jean-Pierre Masquelier

|